Suffolk Technologies BOOST ‘From the Field’: What 200+ Early-Stage Contech and Proptech Startups Tell Us About the Built Environment

By Parker Mundt, Mackenzie Rush & Carly Joos • November 2, 2023

9 min read

About BOOST:

Every year, Suffolk Technologies welcomes the biggest innovators in the Architecture, Engineering, Construction, and Operation (AECO) space for an intense 6-week accelerator program, exposing early-stage entrepreneurs to every facet and detail of the built environment ecosystem. This year, in our fourth edition of the program, we selected seven companies and have been excited to see them progress through challenges they face as founders and technologists in the built world.

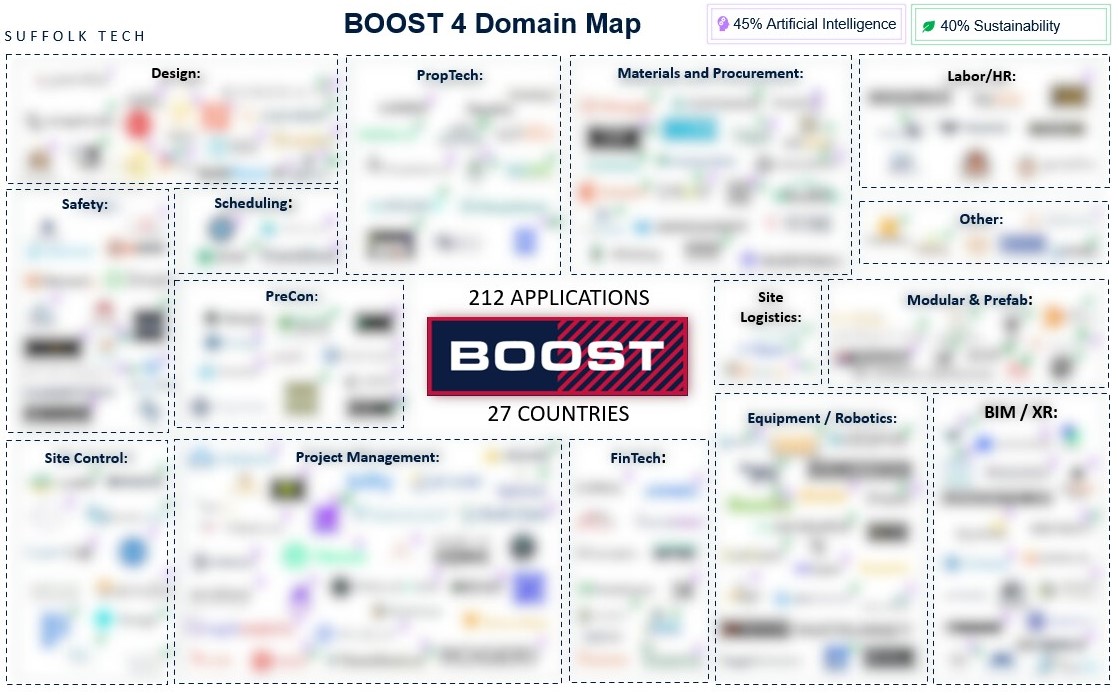

BOOST 4 received 200+ applications from 27 countries this year, more than twice the number of applications than when the program started in 2020. The applicants touched on all aspects of the built environment, with a strong showing across six key themes including artificial intelligence, supply chain efficiency, informed sustainability, field-focused digitization, design optimization, and workforce productivity.

The seven companies selected to participant in this year’s cohort, AGORUS, Emidat, Exodigo, Hammr, KayaAI, Sitelink, and Trunk Tools, are building solutions across these six themes and improving their products and go-to-market strategies with the support of Suffolk Technologies and our 22 industry partners.

Talk to me about the themes…

Artificial Intelligence

The question is not if artificial intelligence (AI) can help change the way we build, but rather how it will affect our industry. AI has already begun to transform our industry significantly – new technologies can automate tasks such as checking 2D design documentation for discrepancies, ensuring code compliance, and identifying coordination clashes. Several emerging technologies are using image recognition to automate laborious tasks such as facade inspections, progress tracking, and surveying. In fact, 45% of BOOST 4 applicants, and almost all chosen participants, note AI as a core feature of their products.

Having said that, AI is unlikely to replace construction professionals anytime soon. Many industry reports rank construction at the bottom of the pack when it comes to AI impact1 and, while we believe this impact will be large, we foresee AI working alongside construction professionals to reduce drudgery and drive productivity instead of displacing workers. AI will serve as a co-pilot to automate back-office tasks, prompt contractually driven actions during a project, and easily serve up information when and where it is needed. The differentiation for AI-enabled applications will be centered around the details and timing of inputs and outputs – AI layers that easily integrate into existing systems and processes will be the quickest and easiest for the industry to adopt.

Supply Chain Efficiency

Construction input costs have increased by an average of 26% in 2021 and 2022 due to factors that include lack of transparency throughout the supply chain and delays caused by macroeconomic disruptions such as COVID-192. With limited options available for reducing the cost of raw materials, construction firms are turning to new technologies to help them track the movement of materials, monitor inventory levels, optimize procurement processes, and reduce material waste, ultimately leading to smoother operations and cost savings. For example, AGORUS is utilizing AI-enabled software and robotics to precisely cut and assemble customized timber members of buildings to be installed rapidly on the jobsite, ultimately reducing assembly time, and mitigating costly waste.

We believe the lack of visibility throughout the supply chain can be addressed with technological solutions. General contractors and developers can increasingly leverage software solutions to capitalize on once hard-to-find purchasing power and begin purchasing larger ticket items, such as electrical and mechanical equipment. Other solutions are empowering the offsite tracking and management of materials. For instance, KayaAI has been building tools to integrate AI-driven visibility into our ecosystems’ pre-existing processes and increase lead time visibility on construction projects.

Informed Sustainability

In an era when sustainable business practices are increasingly becoming a competitive advantage, construction firms are exploring how they can address sustainability challenges and transparently communicate their impact. No matter what path firms choose, the first step will be measuring and reporting on various sustainability metrics to demonstrate commitment to sustainable development and meet the demands of stakeholders, regulators, and the broader community. Helping companies navigate the first step are companies such as Emidat. Emidat helps building material manufacturers easily create and distribute environmental product declarations (EPDs), the foundational impact data for embodied carbon stakeholders can leverage to make informed decisions.

The ability to establish industry-wide sustainability baselines will drive the implementation of new processes and methodologies that can power continuous improvements that reduce the built world’s environmental footprint. Metadata collection and aggregation are critical in the coming years as the U.S. slowly, but surely, adopts and pushes for increased reporting and visibility into the materials and processes used to build. There are two key challenges that this new wave of regulations will present for commercial real estate owners: 1) Getting access to reliable and trusted data, which is most often found at the source (such as manufacturers and producers), but also the most difficult to access, and 2) Helping decision-makers across the value chain prioritize the best ROI solutions when it comes to reducing their impact.

Field-focused Digitization

We are excited to increasingly observe technology tools catching hold with a ‘bottom up’ approach, where adoption starts with superintendents and project managers, rather than a centralized innovation team. The ‘top down’ approach to design, project management, building information model (BIM) creation, and reporting has enabled the industry to set standards, adopt new technologies, enforce consistency, ensure back-office efficiency, and drive continuous improvement in enterprise-wide programs and standard operating procedures. In contrast, the ‘bottom up’ adoption promises to streamline workflows and increase productivity in the field, empower frontline professionals to address challenges with data at their fingertips, and address root causes of project delays and cost overruns.

To reap the full benefits of a streamlined, real-time workflow, the perpetual dissonance between BIM and field updates needs to be solved – a gap Sitelink is trying to address with their AR-powered field app. Their solution was built to enhance collaboration for construction teams by bringing BIM to the jobsite. This explosion of field technology coincides with demographic trends we expect to gain momentum in the coming decade. As more than half of the current labor force phases out of the skilled trades, we expect tech-enabled efficiency gains to become more critical and demanded by the workforce, incentivizing network effects rather than forcing outdated tools on individuals in the field.

Design Optimization

As building designs and code complexity increase, optimizing the time that it takes to create design and construction documents in 2D, and 3D has become a focus for design and construction professionals – and a great seeding ground of many tech companies. With added complexity, the time and effort required from professionals to generate a valid, code-compliant set of drawings has increased tremendously. One way to accelerate the production of these documents is assisting with reality capture of existing site conditions, which helps to not only speed up the design process, but also avoids unexpected problems in the future. This has become especially relevant for project starts. Having accurate information from the outset reduces requests for information in-field, minimizes rework, and streamlines the schedule. Sub-surface mapping solutions, such as the one being developed by Exodigo, can provide a clear picture of the underground, informing partners where to design and build safely with a high level of predictability, and doing so faster and more efficiently than existing intrusive methods.

There are rich opportunities for optimizing design beyond project starts as well. Other solutions focus on AI and automation of certain repetitive design tasks. Today, designs are often created from scratch, rather than leveraging institutional knowledge accumulated through previous projects. Thankfully, pulling in previous details and specs from similar projects from the past is becoming easier with today’s tools, helping architects be more productive with their time. Furthermore, the ability for multiple architects to simultaneously collaborate on a drawing set has circumvented the need for downloading or sharing large file formats, avoiding previously disjointed workflows. With so many components to design, such as balancing aesthetic considerations with functionality, sustainability, and cost-efficiency, technologies that enable a more informed, collaborative design process can meaningfully affect change in the industry.

Workforce Productivity

Workforce productivity stands at the core of the AECO industry’s success and profitability. In an environment where the cost of materials and labor are increasing, optimizing the performance of the construction workforce is critical. From skilled laborers to engineers to project managers to back-office functional roles, harnessing the full potential of human resources is not only essential for meeting deadlines and staying within budget, but also for ensuring the safety and quality of construction projects.

Many startups are addressing issues of productivity in the AECO space. For example, Hammr identified an urgent need among SMB contractors through their social media community (the “Bred to Build” podcast) and addressed those needs by building a tool for automating back-office processes. Other early-stage startups are looking at ways to improve workforce productivity by focusing on the field, solving challenges related to training and upskilling the workforce or aligning pay incentives on the jobsite. Trunk Tools addresses the skilled labor shortage in construction by creating easy to use tools for the deskless workforce, including AI-driven superintendent bots that help answer on-site questions and task-based incentives to drive productivity. With better tools in the field and in the back-office, productivity of the jobsite will increase over time.

What Comes Next

The seven startups selected to participate in the BOOST 4 program spent six weeks working with Suffolk Technologies throughout October and November. The BOOST program allowed them to explore and define new use cases within AECO and refine their products and go-to-market strategies. More than half of all BOOST participants have piloted their technology on Suffolk jobsites and many are also exploring pilots with our Operating Partners including Axiom Builders, Holcim, Sellen Construction, and Century Drywall.

If you are interested in learning more about the BOOST program or becoming involved in the future, please reach out to [email protected] and a member of our team will be in touch.

This year, BOOST is presented in partnership with 22 industry partners including Group Amana, Autodesk, ARCO Murray, Axiom Builders, Century Drywall, Feldman Geospatial, Gunderson Dettmer, Holcim, JLL Spark, Liberty, Liberty Mutual, LMRE, McCusker-Gill, The Martin Trust Center for MIT Entrepreneurship, Moog Construction, Procore, Sellen Construction, Suffolk, Suffolk Design, Swire Properties, Thornton Tomasetti, and Zwick Construction.

Connect with Us

Join Ecosystem

Submit a Pitch

Innovation information for your job. Discover cutting-edge construction industry resources, companies, and projects through our monthly email newsletter.